Nissan has revealed a new approach to electrified powertrain development, which it claims will result in a 30% reduction in development and manufacturing costs by 2026.

Called “X-in-1”, it means core electric vehicle components will be shared between full EV and e-POWER hybrids. This will result in e-POWER models costing the same as conventional internal combustion equivalents by 2026 and full electric cars meeting parity by 2030, it has been promised.

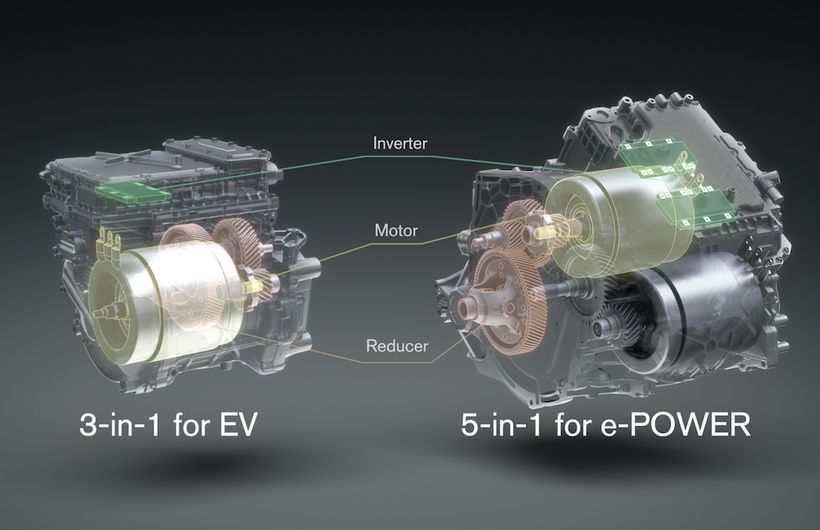

As part of this, Nissan has developed a 3-in-1 powertrain prototype which uses the motor, inverter and voltage reducer for use in EVs. A 5-in-1 prototype, which additionally modularises the generator and increaser, is planned for use in Nissan’s e-POWER vehicles. The core components can be produced on the same production line.

Nissan also claims the size and weight reduction of the new powertrains will improve vehicle driving performance and minimise noise and vibration. The newly developed motor also reduces the use of heavy rare earth elements in manufacturing to 1% or less by weight.

Senior Vice President Toshihiro Hirai, who leads Nissan's powertrain and EV engineering powertrain development, said: “We make the most of our expertise and know-how from our more-than-a-decade long development and production of electrified technologies. Through our innovations in electrified powertrain development, we’ll continue to create new value for customers and deliver 100% motor-driven vehicles – EVs and e-POWER – as widely as possible.”

Sharing components will reduce cost and the use of precious metals

Sharing components will reduce cost and the use of precious metals